Today, let’s take a look at interesting facts about Cerium and answer the following questions: “Why Is Cerium Considered A Rare Earth Element?”, and “Why Is Cerium Considered A Critical Raw Material?”

Check out the rest of the light rare earth elements here – ‘20 Interesting Facts About The Light Rare Earth Elements (LREEs)’

Why Is Cerium Considered A Rare Earth Element?

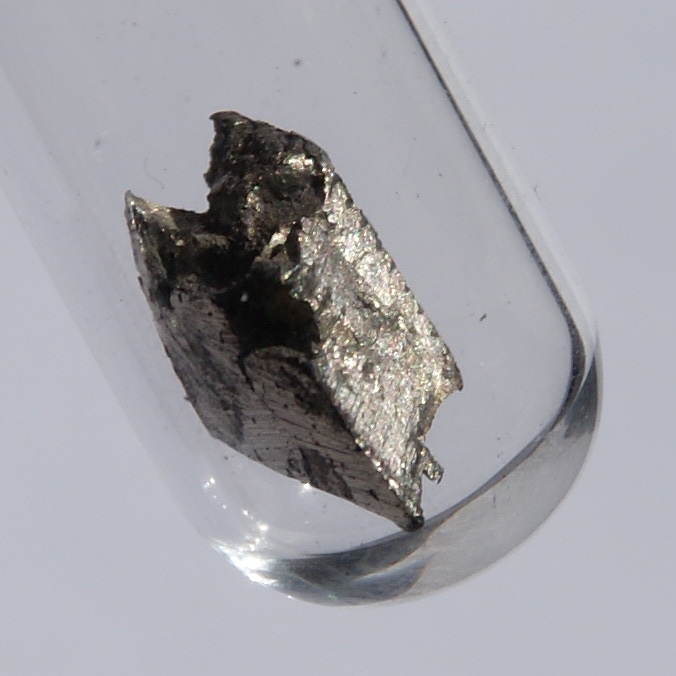

Cerium is considered a rare earth element because it is one of the 15 lanthanide elements that constitute the core group of rare earth elements. With atomic number 58, cerium is the second member of the lanthanide series, positioned between lanthanum (57) and praseodymium (59) in the sequence that extends through lutetium (atomic number 71). As a lanthanide, cerium exhibits the characteristic chemical properties that define this group, though it displays the unique ability to exist in both the typical trivalent state (Ce3+) and a tetravalent state (Ce4+), making it one of only two rare earth elements (along with europium) that commonly exhibits multiple oxidation states. Despite this unique characteristic, cerium’s fundamental chemistry aligns it firmly within the rare earth element family.

Cerium’s geochemical behavior perfectly aligns with the defining characteristics of rare earth elements. Like all REEs, cerium has a high charge and large ionic radius that impedes its incorporation into common rock-forming minerals, causing it to concentrate with other rare earth elements during magmatic processes. Cerium invariably occurs with other REEs in nature, particularly in the primary rare earth minerals bastnäsite ((Ce,La,Nd,…)CO3F), where it is often the dominant REE, as well as in monazite ((REE,Th)PO4) and other REE-bearing minerals. The notation for bastnäsite specifically lists cerium first, reflecting its typical dominance in this mineral. As stated in the documents, “REEs can substitute for one another in crystal structures, and multiple REEs typically occur within a single mineral,” and cerium exemplifies this behavior by occurring alongside other lanthanides in predictable ratios.

From historical, industrial, and practical perspectives, cerium epitomizes the rare earth element group. Discovered in 1803 by Jöns Jakob Berzelius and Wilhelm Hisinger, cerium was named after the asteroid Ceres and was one of the first rare earth elements identified. Industrially, cerium’s applications demonstrate its integration with other rare earth elements: it is the primary component of mischmetal (containing “65% cerium, 35% lanthanum”), used in steelmaking and lighter flints. Cerium oxide serves as a unique glass polishing agent where “the polishing action of CeO2 depends on both its physical and chemical properties, including the two accessible oxidation states of cerium, Ce3+ and Ce4+.” Cerium is also essential in automotive catalytic converters and petroleum refining catalysts, applications that leverage its rare earth chemistry. The fact that “virtually all polished glass products, from ordinary mirrors and eyeglasses to precision lenses, are finished with CeO2” demonstrates how cerium’s rare earth properties have made it industrially indispensable.

The combination of cerium’s position in the lanthanide series, its characteristic REE chemistry despite having two oxidation states, its consistent co-occurrence with other REEs as the dominant component in most deposits, and its industrial applications alongside other rare earth elements unequivocally establishes cerium as a rare earth element.

Why Is Cerium Considered A Critical Raw Material?

Cerium is considered a critical raw material due to its unique and irreplaceable properties in multiple industrial applications, combined with severe supply concentration risks. Despite being the most abundant rare earth element at 66.5 parts per million crustal abundance, cerium’s criticality stems from its specialized applications where no adequate substitutes exist. Most notably, “virtually all polished glass products, from ordinary mirrors and eyeglasses to precision lenses, are finished with CeO2.” The polishing action of cerium oxide is unique because it “depends on both its physical and chemical properties, including the two accessible oxidation states of cerium, Ce3+ and Ce4+, in aqueous solution.” This dual oxidation state enables a chemical-mechanical polishing action that no other material can replicate. Additionally, cerium-based catalysts are essential in automotive catalytic converters for reducing carbon monoxide emissions and in petroleum refining for cracking heavy hydrocarbons.

The extreme concentration of cerium supply in China creates critical vulnerabilities for global industries. Between 2011 and 2017, China produced approximately 84% of the world’s rare earth elements, while the United States contributed only about 4% during its limited production from 2012-2015. Chinese deposits contain exceptional cerium concentrations – Bayan Obo contains 50.00% cerium oxide of total REO, while other Chinese deposits show similar enrichment: Maoniuping (47.56%) and Weishan (47.76%). When China announced export restrictions in 2010 through quotas, licenses, and taxes, industries dependent on cerium faced immediate supply concerns. The vulnerability is compounded by the fact that cerium, despite being abundant in rare earth deposits, cannot be selectively mined – its production is tied to the extraction and processing of the entire rare earth suite.

The strategic importance of cerium extends across multiple critical sectors that underpin modern society. The glass industry, identified as “the leading consumer of REE raw materials,” depends entirely on cerium oxide for precision polishing of flat panel displays, computer monitors, television screens, and optical lenses – technologies fundamental to the information economy. In environmental applications, cerium’s role has “increased markedly over the past three decades” as an essential component in both petroleum fluid cracking catalysts and automotive pollution-control catalytic converters. The use of cerium-based catalysts in petroleum refining enables refineries to “obtain significantly more product per barrel of oil processed,” making cerium critical for fuel production efficiency. Furthermore, cerium serves as the primary component of mischmetal (containing “65% cerium, 35% lanthanum”) used in steelmaking to remove impurities and produce special alloys.

The combination of cerium’s unique chemical properties, lack of substitutes, and concentrated supply chain firmly establishes its critical status. While cerium oxide prices remained relatively low at $1-2/kg during the review period due to its abundance in rare earth ores, this masks the element’s true criticality. Any disruption to rare earth mining or processing would immediately impact numerous industries, from consumer electronics to petroleum refining. Expert panels from the National Research Council, U.S. Department of Energy, and European Commission have consistently ranked rare earth elements including cerium as having high “criticality” ratings.

The statement that cerium “has dozens of applications, some highly specific” with “no substitute known” for many uses encapsulates its critical nature. The fiscal year 2024 National Defense Stockpile plan includes 550 metric tons of cerium for potential acquisition, reflecting official recognition of its strategic importance. The convergence of cerium’s irreplaceable role in glass polishing, environmental catalysts, and metallurgy, combined with supply chain concentration in China and growing demand from technology sectors, establishes cerium as a critical raw material whose availability directly impacts multiple foundational industries.

Interesting Facts About Cerium

- Cerium is the most abundant of all rare earth elements, making up about 0.0046% of Earth’s crust – more common than tin or lead.

- It’s the only lanthanide that can exist in both +3 and +4 oxidation states in aqueous solution under normal conditions, making it uniquely versatile in chemical reactions.

- Cerium exhibits the largest liquid range of any element – it remains liquid from 798°C to 3,443°C, a span of 2,645 degrees.

- When struck or scraped, cerium produces sparks that burn at temperatures up to 3,000°C, making it ideal for lighter flints and ignition devices.

- Cerium oxide nanoparticles can switch between Ce³⁺ and Ce⁴⁺ states, acting as powerful antioxidants that can neutralize free radicals in biological systems.

- It undergoes a unique phase transition at -150°C where it experiences a 16% volume collapse – one of the largest volume changes known for any element.

- Cerium-doped yttrium aluminum garnet (YAG:Ce) phosphors are crucial for white LED production, converting blue light to a broad yellow emission spectrum.

- The element self-ignites in air at just 65-80°C when in finely divided form, one of the lowest auto-ignition temperatures of any metal.

- Cerium(IV) oxide has a remarkable “self-healing” property – it can release and absorb oxygen reversibly without changing its crystal structure.

- It’s the only rare earth element extracted on an industrial scale through oxidation and selective precipitation rather than ion exchange or solvent extraction.

- Cerium compounds exhibit strong UV absorption below 400 nm while remaining transparent to visible light, making them perfect for UV-blocking glass.

- The element has an unusually low melting point (798°C) for a rare earth metal, attributed to its unique electronic configuration with one 4f electron.

- Cerium catalysts can reduce diesel particulate emissions by up to 80% and enable combustion at temperatures 100-150°C lower than normal.

- It possesses four allotropic forms, more than most rare earth elements, with transitions occurring at -150°C, 25°C, and 726°C.

- Cerium anomalies in marine sediments serve as paleoredox indicators, revealing ancient ocean oxygen levels from millions of years ago.

- The element’s photocatalytic properties allow cerium oxide to break down organic pollutants under UV light while regenerating itself.

- Cerium has an exceptionally high hydrogen storage capacity, absorbing up to 3.8 hydrogen atoms per cerium atom to form CeH₃.₈.

- Its compounds show thermochromic behavior – cerium sulfide changes from red to yellow when heated, used in temperature-indicating paints.

- Cerium-stabilized zirconia exhibits ionic conductivity 100 times higher than pure zirconia at 1000°C, crucial for solid oxide fuel cells.

- The element displays the strongest “mixed valence” behavior among lanthanides, with some compounds containing both Ce³⁺ and Ce⁴⁺ simultaneously in the crystal lattice.

Thanks for reading!